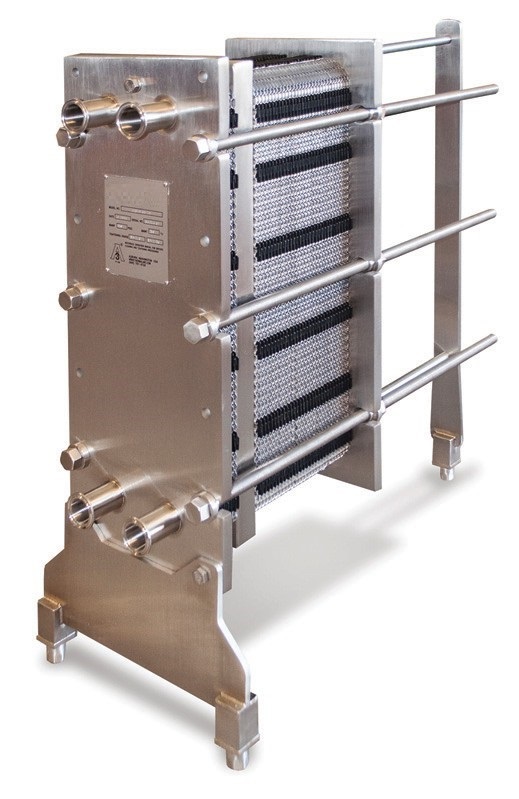

Brazed Plate Heat Exchanger

Contact Now

- TEL:+86-13395157738

- Email:sales@greenheatexchanger.com

Brazed Plate Heat Exchanger features

The stainless steel sheets are brazed together without gaskets and frames. The contact points help hold the boards tightly to withstand high voltages. The function of the brazing material is to hermetically seal the stainless steel package. GHE's brazed heat exchangers are brazed at all contact points to ensure optimum heat transfer efficiency and pressure resistance. The advantages of brazed plate heat exchangers are small sized, light weighted, and can withstand pressures up to 4.5Mpa. GHE offers flexible custom designs to meet customer’s specific requirements to ensure the most cost-effective solution for customers' heat transfer tasks.

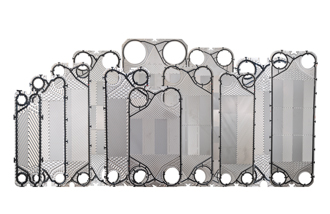

Brazed Plate Heat Exchanger Material

The main components of BPHE (brazed plate heat exchanger) are stainless steel corrugated plates and copper sheets. The stainless steel plates are brazed together by brazing material (copper or nickel) in a vacuum furnace. Copper brazed heat exchangers are used in a variety of applications. However, for food or applications involving corrosive liquids, a nickel brazed unit is recommended.

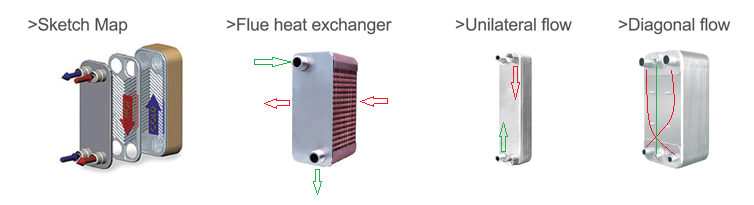

Brazed plate heat exchanger Fluid Flow principle

The basic flow principle in GHE brazed heat exchanger is parallel(except dual system BPHE)and current flow,this design makes easier installation.

1) Flow principle in brazed plate heat exchanger Evaporator

In a brazed plate heat exchanger, the two media always flow in opposite directions, it is called current flow. The two-phase refrigerant (vapor + liquid) enters the bottom left of the heat exchanger, and the vapor quality depends on the operating conditions of the application. Evaporation of the liquid phase occurs within the channels and some degrees of superheat are always requested.

2) Flow principle in brazed plate heat exchanger Condenser

It shares the same components as evaporator. Hot refrigerant enters from the upper left of the heat exchanger and begins to condense on the channel surfaces until fully condensed, and subcooling is also required.

3) Multipass Design brazed plate heat exchanger

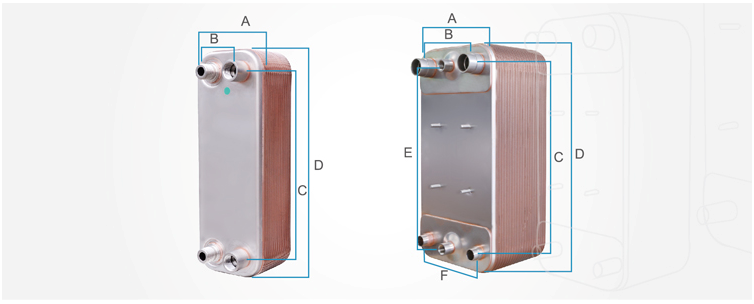

The heat exchanger can be designed as multi-channels according to customer's requirements. We can offer different connection positions, types and sizes based on customer specific designs.

4) Dual system brazed heat exchanger design

What is a dual system? A dual circuit refers to two refrigerant streams and one water stream. Designed as a cross-flow design, that is, the brazed plate heat exchanger can connect two independent refrigerant circuits. This design ensures that each refrigerant circuit is exposed to the entire water flow. The main advantage is that the water cooling performance can still be maximized when only the compressor is running.

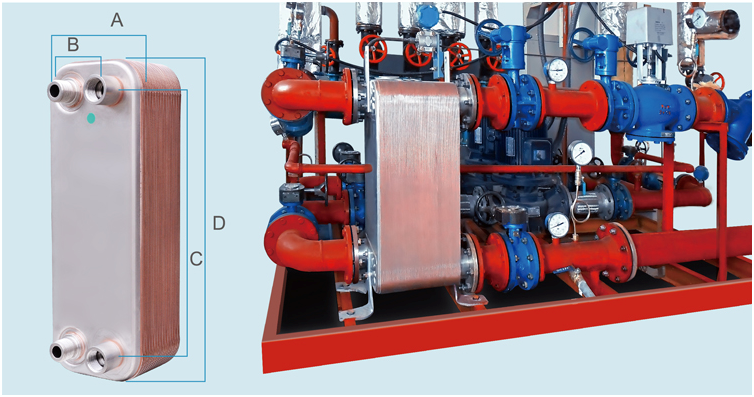

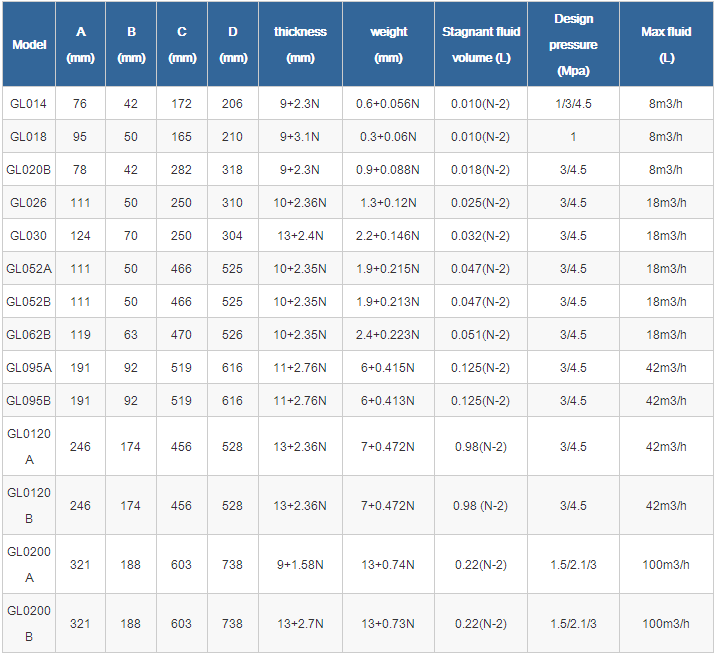

Brazed Plate Heat Exchanger Specification

Notes:

N* is plate number

High efficiency heat exchanger

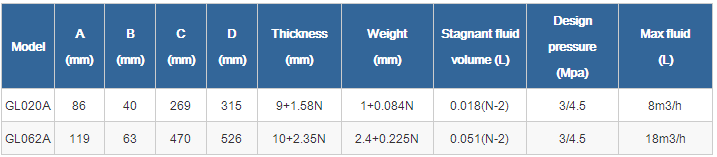

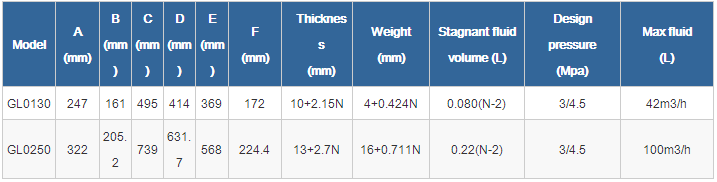

Our GL020, GL062 series, GL0130, GL0250 are specifically developed for R410A refrigerant, which is ideal alternative of R22. R410A efficient heat exchanger is not only resistant to high pressure, but also with less refrigerant to achieve the same cooling effect. GL020 and GL062 are unilateral flow. GL0130 and GL0250 are diagonal flow. They can work from the power range of 1KW to 250KW

Dual System*

Notes:

N* is plate number

Get Price And Support

Please leave your telephone number or mobile phone nubmer for emergency contact, in case we can not reach you by mail.

- 2023-09-05API oil cooler replacement with ASME standard

- 2023-01-09Heat Pump Heat Increase in Europe market

- 2022-09-30Plate Heat Exchanger for Pasteurization

- 2022-09-30Wort Pre-heater and Chiller Service

- 2022-09-30How a BPHE work and to be designed?

- 2022-09-30Ammonia evaporating -Semi-weld PHE