Shell-Tube ETporator Specification

Contact Now

- TEL:+86-13395157738

- Email:sales@greenheatexchanger.com

Features:

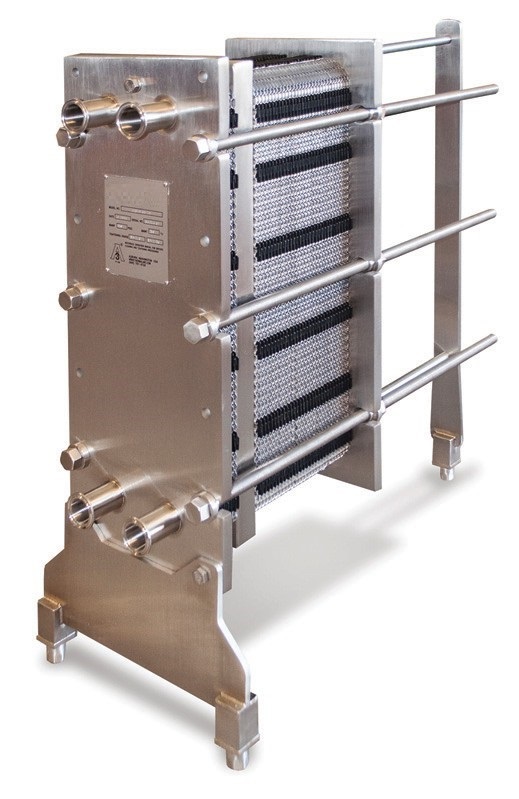

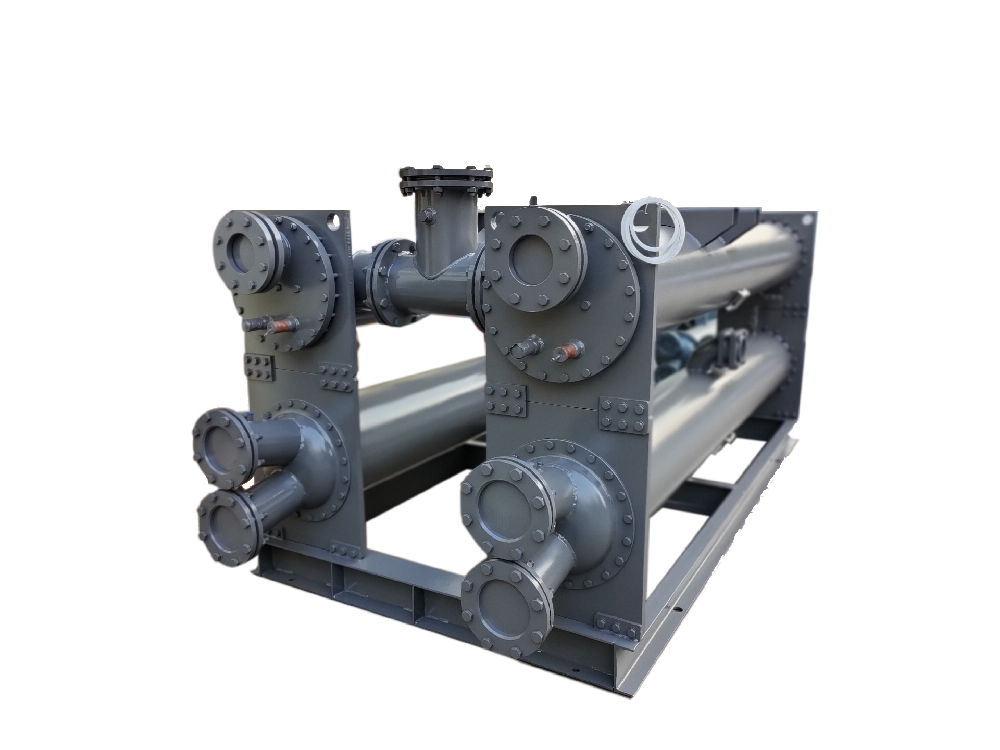

The shell-tube heat exchanger has a solid structure and can be manufactured with a variety of materials. It has strong adaptability, and is especially widely used in high temperature, high pressure and large devices.

Typical Application

Evaporator in Screw chiller system

Dry shell and tube evaporators are mainly used in Freon refrigeration systems. The refrigerant liquid of this evaporator goes through the tube side, and the refrigerant charge is small. Its structure is similar to flooded evaporator, the difference is that a number of circular baffles with truncated arc-shaped areas are arranged upside down on multiple horizontal smooth copper tubes. After throttling, the refrigerant liquid enters the tube side from the inlet below the end cover at one end of the evaporator. After 2-4 processes to absorb heat, it is drawn out from the air outlet above the end cover on the same side. The flow of refrigerant in the shell-and-tube dry evaporator has different forms such as single-inlet and single-outlet, double-inlet and single-outlet, double-inlet and double-outlet, etc. The cooling tube is usually a copper tube with an outer diameter of 12-16mm. There are longitudinal fins inside the tube. The mass flow rate in the pipe is generally 180-200kg/(nf-s), and the number of partitions should ensure that the coolant flows laterally. Tube bundle speed 0.5—1.5 m/s.

The advantages of the dry evaporator are: ① Less liquid, about 40% of the tube volume; ② Less affected by the static pressure of the refrigerant liquid; ③ Easy to drain oil; ; ⑤ Easy to control the refrigerant liquid level; ⑥ Compact structure; ⑦ High heat transfer coefficient. The disadvantage is that the refrigerant supply in the tube group is not easy to be uniform, and the production and installation of the baffle are more troublesome. Leakage and side flow are easy to occur between the tube hole and the tube of the refrigerant side baffle, and between the outer circumference of the baffle and the shell. , thereby reducing the heat transfer effect.

GHE provide customers in HVAC and refrigeration industries with quality and stabilization shell tube evaporators. We support customers to create value with our honest attitude and competitive price .

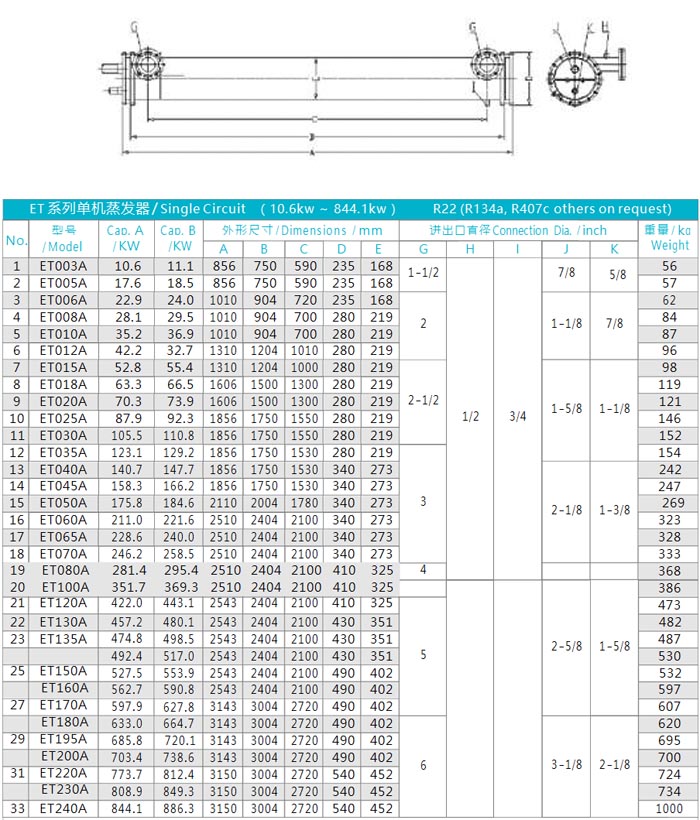

ETporator Specification

1) Single Circuit

Note :

1.Working Conditions (Cap. A):Te=2℃, Tc=40℃, Tsuc=5℃, Ti=12℃, T0=7℃;

2.Working Condition (Cap. B):Te=2℃, Tc=35℃, Tsuc=5℃, Ti=15℃, T0=8℃;

3.当R134a介质时 / change as R134a, 其换热量 / Heat Exchange Cap. QR134a=0.8QR22;

当R407c介质时 / change as R407c, 其换热量 / Heat Exchange Cap. QR407c=0.9QR22;

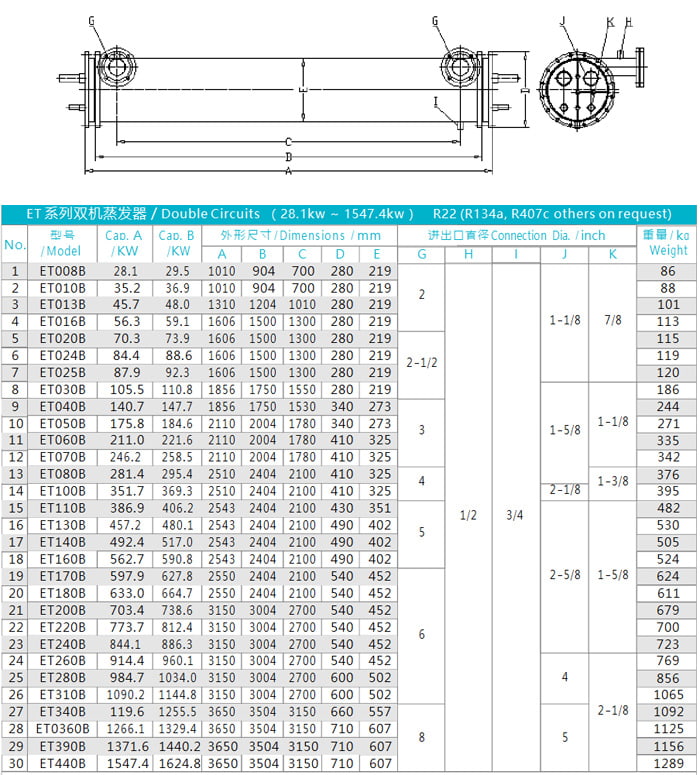

2)Double Circuit

Note:

1. Working Conditions (Cap. A):Te=2℃, Tc=40℃, Tsuc=5℃, Ti=12℃, T0=7℃;

2.Working Condition (Cap. B):Te=2℃, Tc=35℃, Tsuc=5℃, Ti=15℃, T0=8℃;

3.当R134a介质时 / change as R134a, 其换热量 / Heat Exchange Cap. QR134a=0.8QR22;

当R407c介质时 / change as R407c, 其换热量 / Heat Exchange Cap. QR407c=0.9QR22;

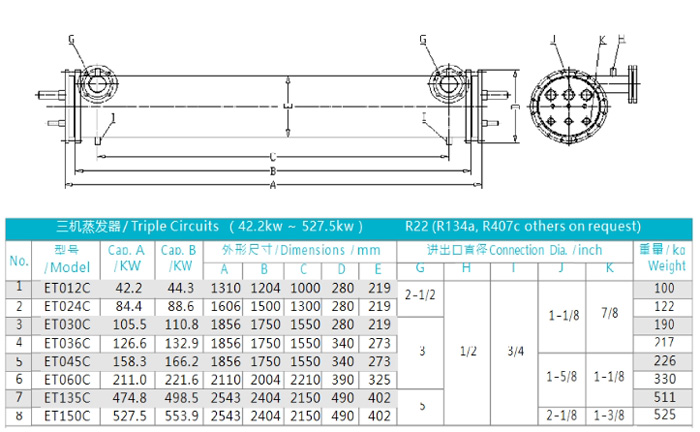

3)Triple Circuit

Note :

1.Working Conditions (Cap. A):Te=2℃, Tc=40℃, Tsuc=5℃, Ti=12℃, T0=7℃;

2.Working Condition (Cap. B):Te=2℃, Tc=35℃, Tsuc=5℃, Ti=15℃, T0=8℃;

3.当R134a介质时 / change as R134a, 其换热量 / Heat Exchange Cap. QR134a=0.8QR22;

当R407c介质时 / change as R407c, 其换热量 / Heat Exchange Cap. QR407c=0.9QR22;

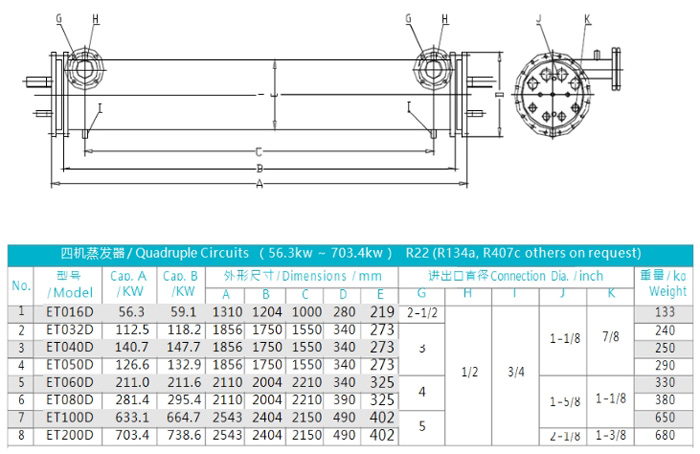

4)Quadruple Circuits

Note :

1.Working Conditions (Cap. A):Te=2℃, Tc=40℃, Tsuc=5℃, Ti=12℃, T0=7℃;

2.Working Condition (Cap. B):Te=2℃, Tc=35℃, Tsuc=5℃, Ti=15℃, T0=8℃;

3.当R134a介质时 / change as R134a, 其换热量 / Heat Exchange Cap. QR134a=0.8QR22;

当R407c介质时 / change as R407c, 其换热量 / Heat Exchange Cap. QR407c=0.9QR22;

Get Price And Support

Please leave your telephone number or mobile phone nubmer for emergency contact, in case we can not reach you by mail.

- 2023-09-05API oil cooler replacement with ASME standard

- 2023-01-09Heat Pump Heat Increase in Europe market

- 2022-09-30Plate Heat Exchanger for Pasteurization

- 2022-09-30Wort Pre-heater and Chiller Service

- 2022-09-30How a BPHE work and to be designed?

- 2022-09-30Ammonia evaporating -Semi-weld PHE